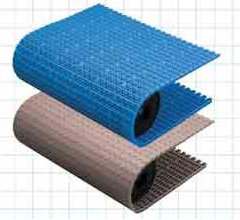

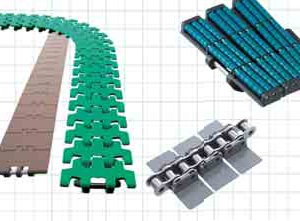

Plastic Modular Chain uses an alternating combination of interconnected modular engineering plastic links to transport goods in large quantities on wide, belt-shaped conveyors. Chain-sprocket engagement ensures reliable drive without any slips. Three different link types are available according to the application and type of goods being conveyed: closed, open, and net types. Plastic Modular Chains are in demand in the corrugated cardboard, automobile, and food and beverage industries to replace conventional conveyors in a variety of applications.

Plastic Top Chain

|

|

|

|

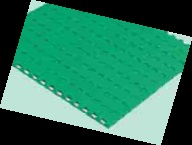

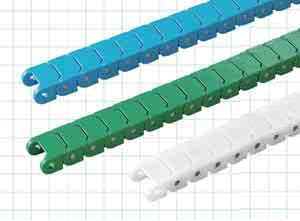

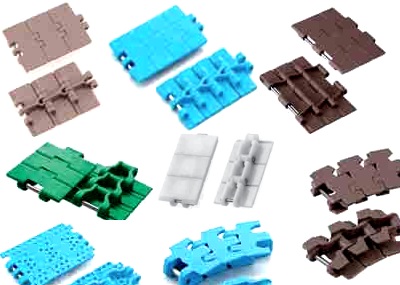

Plastic Top Chain Top plates and chains are made of engineering plastic and are connected using engineering plastic or stainless steel pins. Other types feature plates of engineering plastic combined with steel, nickel-plated steel, lube-free steel, or stainless steel base chains. Yet another type includes rollers attached to two strands of stainless steel or nickel plated chains. The rollers rotate freely and reduce line pressure during accumulation. Plastic top chains are used mainly in the food processing, beverage, dairy, and packaging industries. |

|

|

A smaller chain pitch allows use of sprockets with a smaller outer diameter, reducing dead space between conveyors and transitioning goods more smoothly. |

|

|

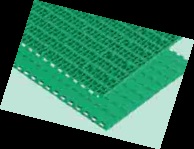

Combination of steel base chain and plastic covers. |